[ad_1]

It took a pivot for Amper to search out its footing. Based in 2016 with hopes of constructing a wise circuit breaker for the house, the corporate needed to take an extended take a look at the their place out there — or lack thereof.

“We received into HAX with that concept, after which fully invalidated it,” co-founder and CEO Akshat Thirani says with amusing. “For just a few weeks, we have been simply in a sort of limbo. We knew there’s quite a bit behind electrical energy, based mostly on the house power information we’ve seen. I used to be in Shenzhen. All the things simply collided, and a brand new firm — in a way — was born.”

Thirani says he drew on his childhood in India for inspiration, coming from a household that ran factories for a number of generations. Fashioned in Chicago, the place its founders went to highschool at Northwestern, the workforce developed a system designed to assist drag producers into the twentieth century.

Amper’s know-how is successfully a plug and play resolution that retrofits manufacturing unit machines. The small containers plug into the wall and clamp on to the machine’s twine to measure power circulate. From there, it may extrapolate key data, together with output and whether or not the system is on-line.

“We ship out this DTC field,” says Thirani. “It’s sort of a DTC, self-installed package. It takes about 10 minutes to put in on any sort of machine. That’s been our development engine. We simply give it away, of us can attempt it without spending a dime and take the product for a spin. We’re deployed in 250 factories, globally. After that preliminary product-fit stage, we’ve been solely doing distant gross sales.”

Picture Credit: Amper

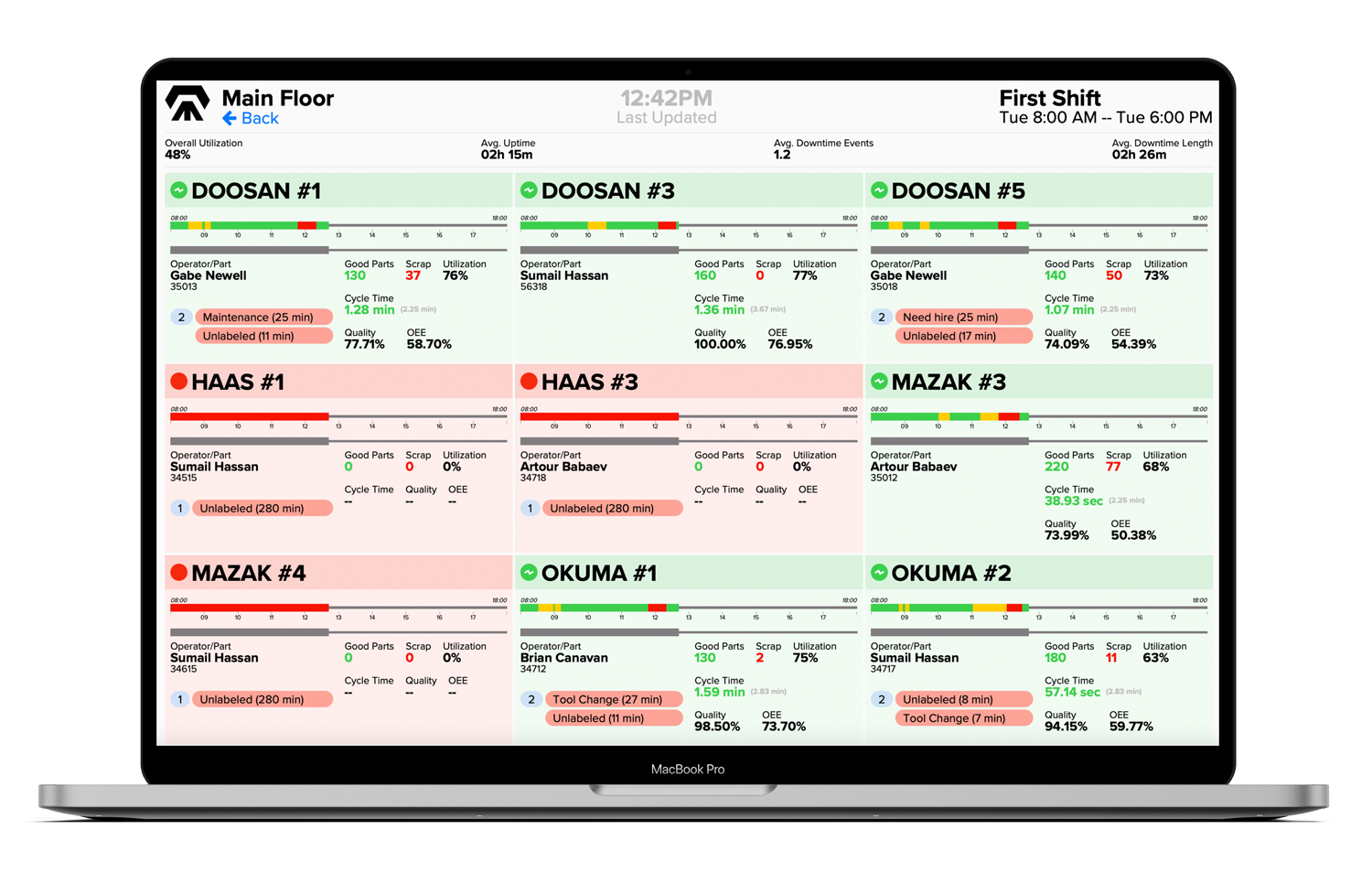

From there, the system takes round per week to completely calibrate. After that on-boarding interval, the entire pertinent data is obtainable in a single dashboard, together with the machine’s standing and the variety of elements it’s output. The insights it collects finally aren’t as deep that people who would possibly come from a brand new machine with built-in sensing, however it’s a little bit of a tradeoff that comes with the benefit of set up and value. Successfully it’s a low barrier of entry for digitizing factories’ present programs.

Having already raised a $3.5 million seed, the corporate right now introduced an $11 million Collection A led by Lewis & Clark Ventures and that includes Basis Capital, Corazon Capital, Sluggish Ventures, SOSV, Converge VC and GTMfund. The funding will go, partially, to constructing out the workforce from slightly below 20 to greater than 50 within the coming years. It can even be used to commercialize its present product and future R&D.

“Manufacturing is large,” says Thirani. “You need to construct merchandise which are consumerized and accessible to all types of producers. I had this reminiscence with my dad — when you needed to purchase any sort of know-how, you needed to speak to salespeople and consultants. I had this imaginative and prescient that you must have the ability to go on the web site, purchase a product, know precisely what it prices and simply have the identical expectation that we do as customers.”

[ad_2]

Source link