[ad_1]

Q5D’s proposition is an easy one: use robotics to automate the method of manufacturing wiring harnesses for electronics. It’s one which — surprisingly — is commonly nonetheless executed by hand, owing to its general complexity. It’s a course of, the corporate is fast to level out, that hasn’t actually modified all that a lot over the earlier century. Turning issues over to machines would assist pace up the method of producing (a particular plus amid the entire present gradual downs), decrease prices and mitigate human error.

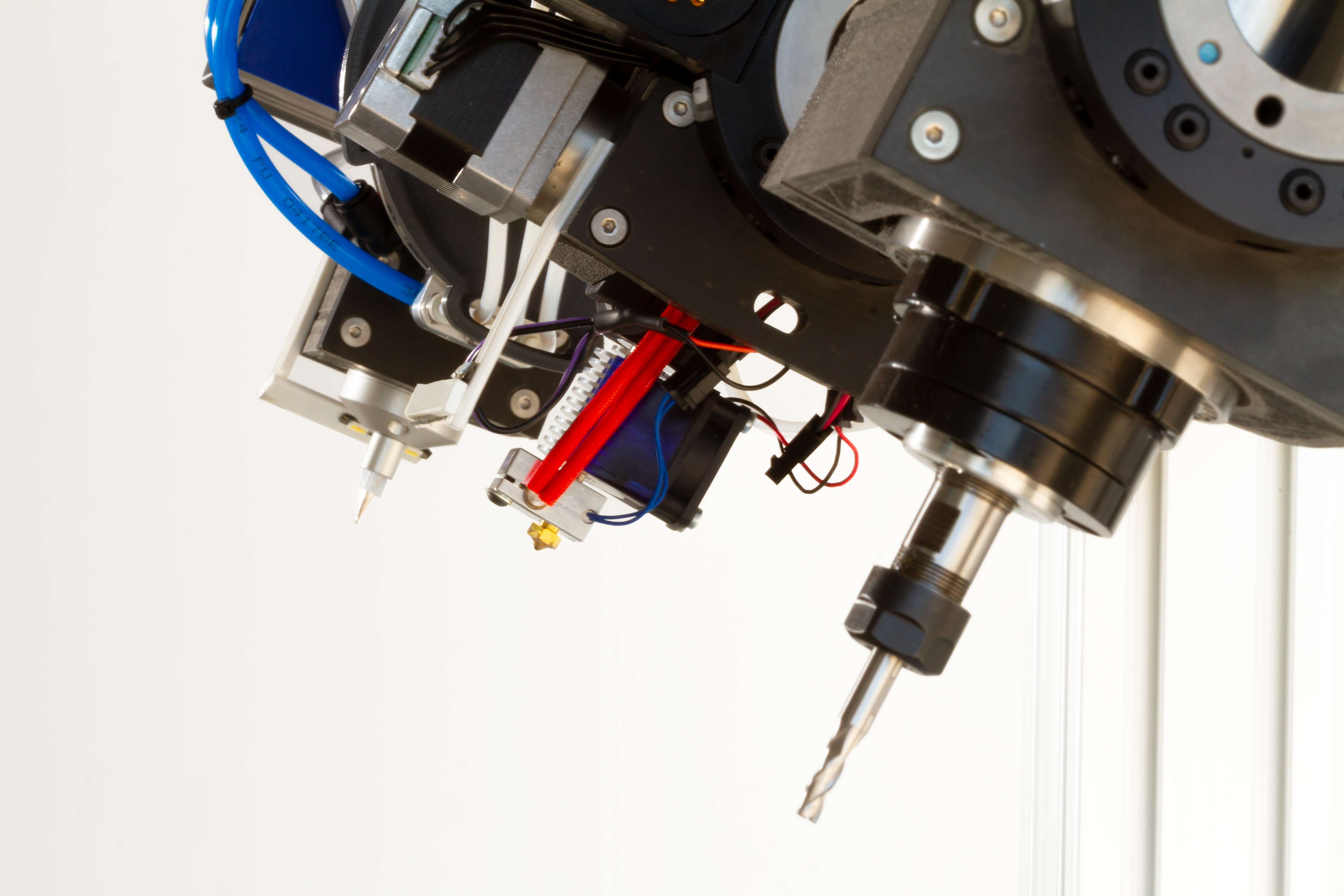

The Bristol, U.Ok. startup was based in 2019 by Steve Bennington and Chris Elsworthy, who had been beforehand concerned in Cella Vitality and CEL-UK and now function CEO and CTO, respectively. In actual fact, the agency is definitely a three way partnership between CEL-UK — an organization that makes 3D printers (together with the Robox model) — and M-Solv, which makes machine instruments for electronics manufacturing.

Picture Credit: Q5D

Q5D is a HAX hardtech startup program alum, with that agency’s guardian, SOSV, collaborating in its newly introduced seed spherical. “Laying wiring inside merchandise is among the most handbook and tedious components of producing. Q5D’s course of and merchandise are elementary in closing the loop for automation in superior manufacturing,” HAX associate Duncan Hunter says in a launch tied to the funding.

The $2.7 million seed is led by Chrysalix Enterprise Capital and options further participation from the Rainbow Seed Fund. The cash shall be used to scale up its know-how, which is at present getting used primarily by aerospace purchasers, together with Safran and Oxford Area Methods. Client electronics and automotive are additionally on the desk, although the agency is fast to notice that the know-how could be deployed throughout a particularly broad vary of classes — the first qualifier being electronics which have built-in wiring programs.

“It is a time of nice change—the speedy electrification of our transport programs and the rising perform of every thing from washing machines to cellphones signifies that wiring is changing into extra advanced and labor intensive,” Bennington says within the launch. “The best way the world has made wiring for the final 80 years has to vary.”

[ad_2]

Source link